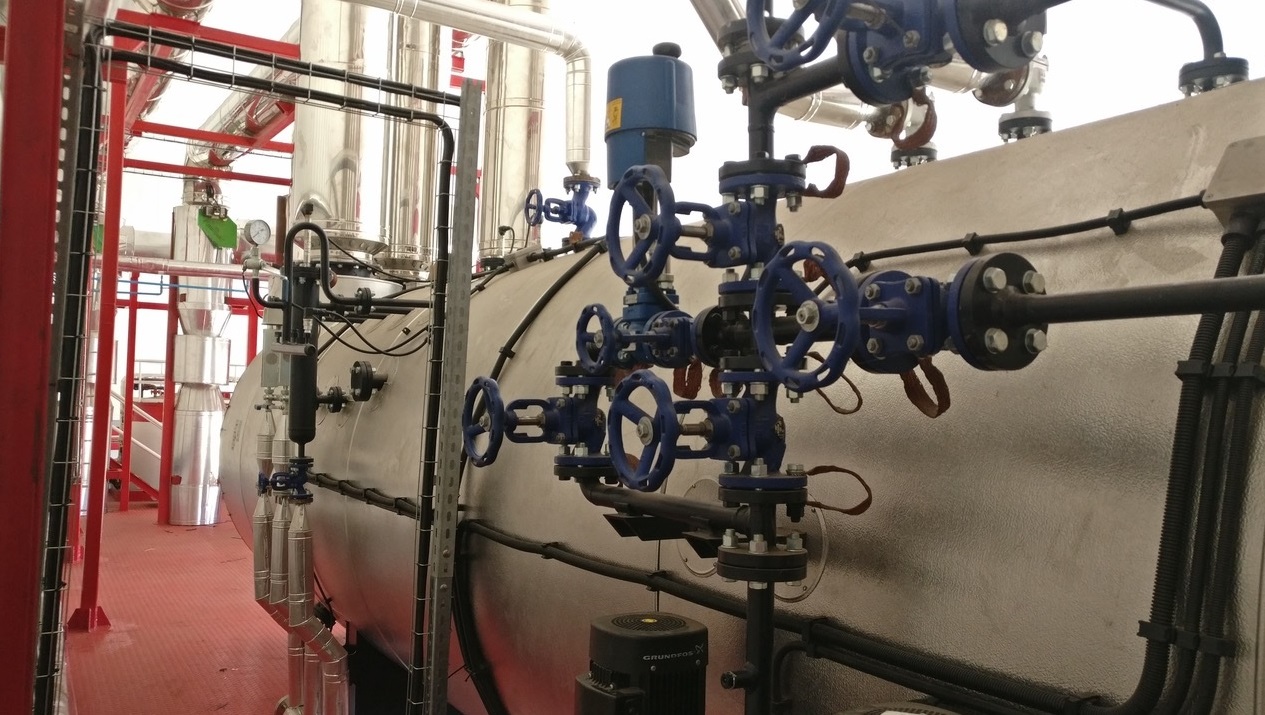

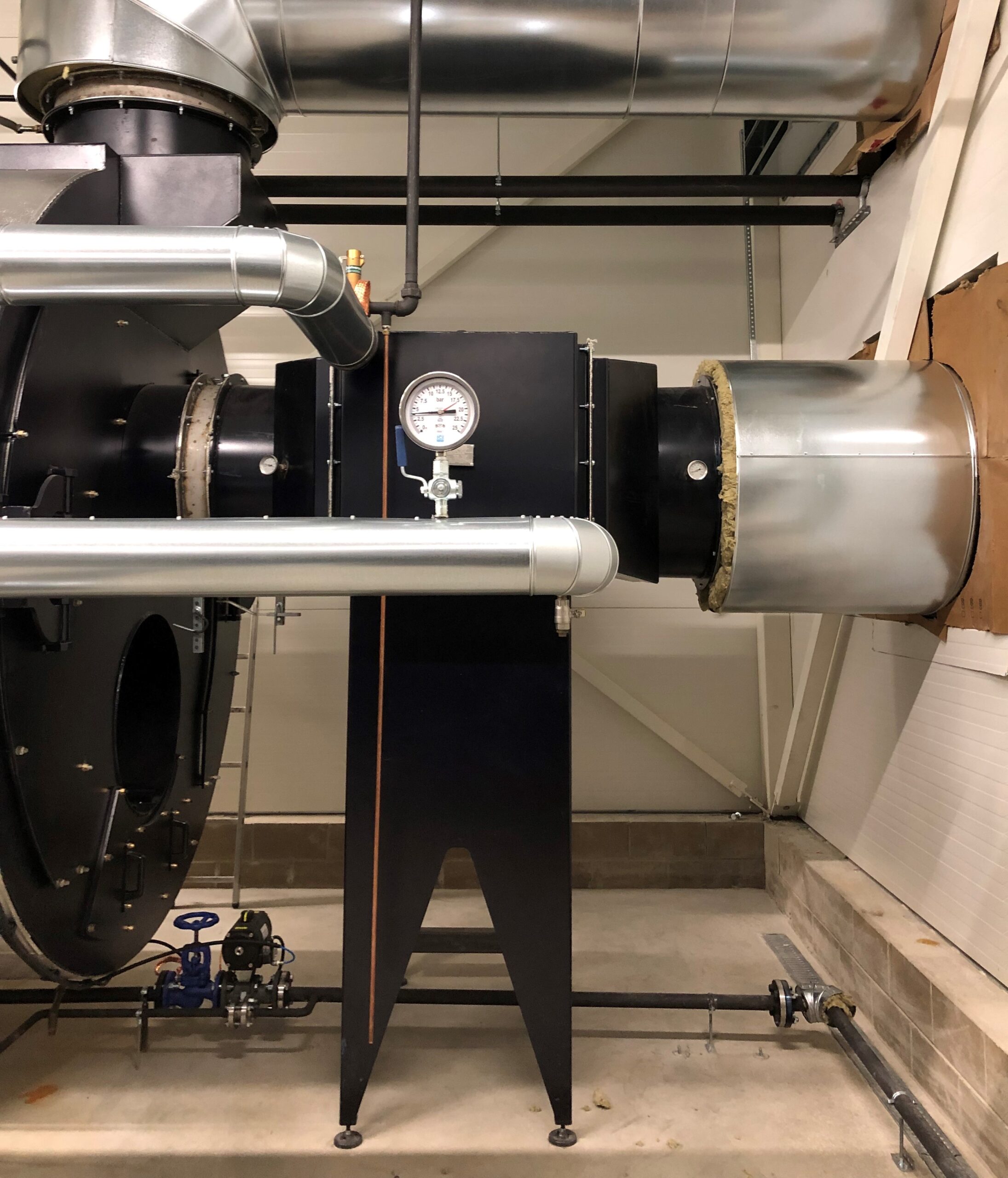

La gamma GX presenta generatori di vapore monoblocco di prestazioni eccellenti, progettati per dare la massima garanzia di affidabilità e durata. Tutti i modelli hanno focolare ondulato e dimensionato per ottenere carichi termici ridotti e consentire un funzionamento ottimale, anche in condizioni di lavoro gravose. Una gamma completa in grado di soddisfare una grande varietà di applicazioni, disponibile anche con surriscaldatore (GX S) e sezioni a recupero fumi (GX C).

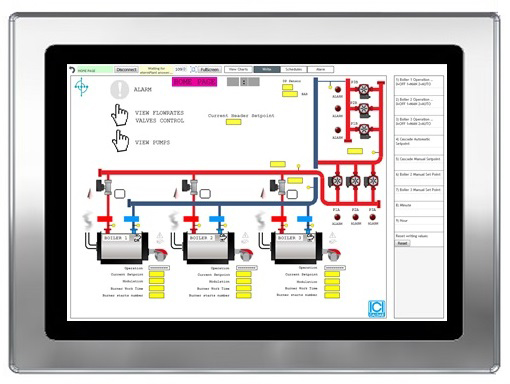

Quadro di comando con display touch screen da 15” per la visualizzazione grafica personalizzata della centrale termica (sinottico). Il quadro può essere collegato via bus a quadri eterm di gestione…